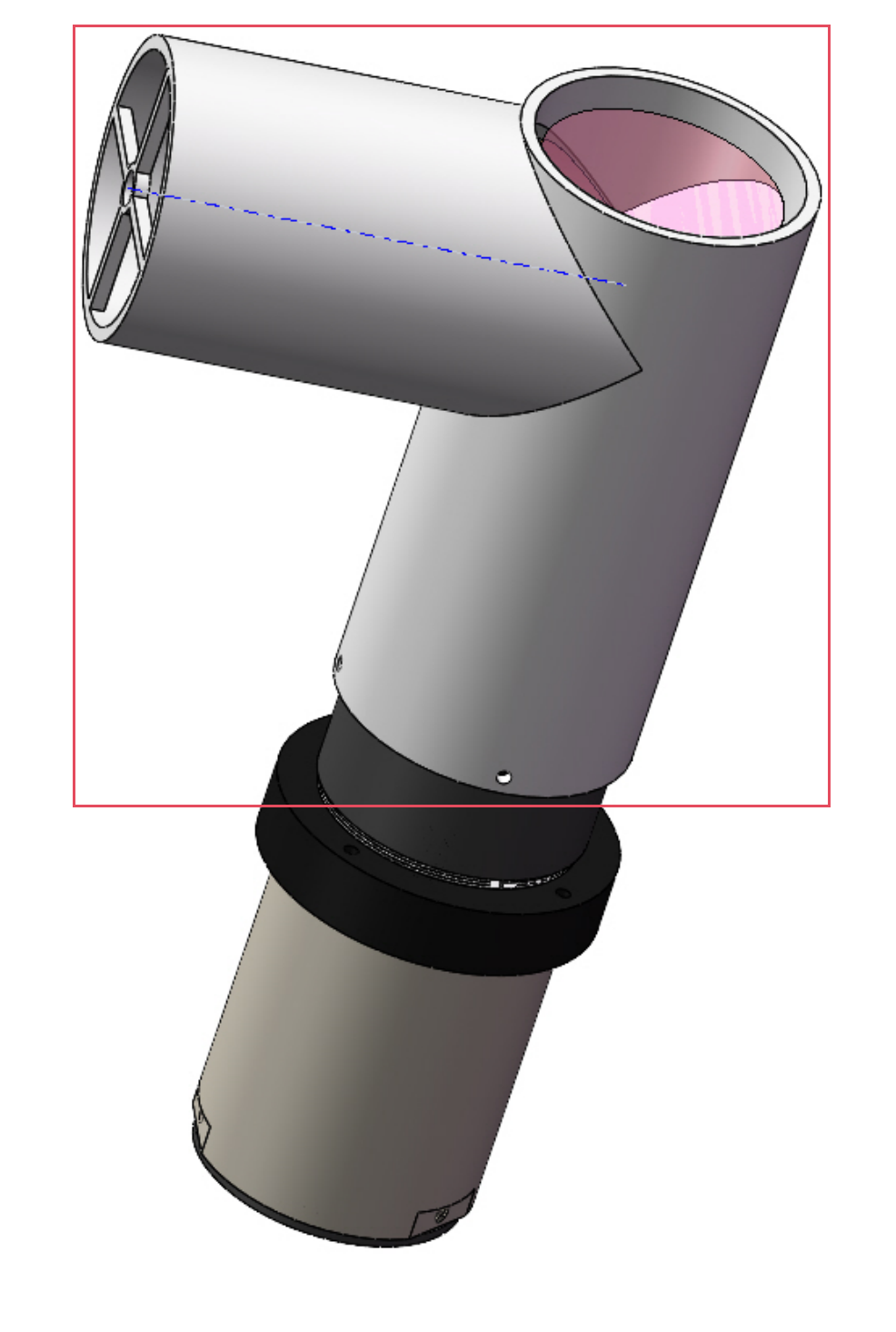

The fiber-coupling technology for high-energy pulsed lasers is a critical process that enables efficient transmission of high-power, high-peak-power nanosecond pulses through optical fibers. This process requires precise matching of optical parameters to the laser specifications, along with fine-tuned alignment of components. This product integrates and packages these components into a unified module, significantly enhancing coupling effeciency and stability. It is compatible with a wide range of laser application scenarios espically for nanosecond lasers—transforming them from bulky, stationary equipment into flexible and compact processing tools.

| Category | Parameter | Typical Value |

| Core Energy /Power | Maximum Single-Pulse Energy | 50 mJ@1.2 mm Fiber Diameter |

| Peak Power Density | 30GW/cm2 | |

| Coupling Efficiency | 80% | |

| Fiber Parameters | Fiber Interface | D80,SMA905(D80 recommanded) |

| Fiber Diameter | 1.2 mm | |

| Fiber Type | Multimode Fiber | |

| Numerycal Aperture | >0.22 | |

| Laser Parameters | Laser Wavelength | 800 nm-1550 nm |

| Pluse Width | >10 ns@50 mJ | |

| Repetition Rate | <20 Hz | |

| Other | Interface Monitor | Optional Auxiliary Coupling-Monitor |

1.Laser-Induced Breakdown Spectroscopy (LIBS):

Applications: Employed for elemental composition analysis (e.g., in the Curiosity Mars Rover), environmental monitoring, and more.

Advantages: By utilizing an optical fiber to deliver the laser pulse to the sample, and another to collect the plasma spectroscopic signal, the structure of LIBS system is greatly simplified, which allows the system to operate effectively in harsh or remote environments (such as space, deep-sea, or industrial field sites).

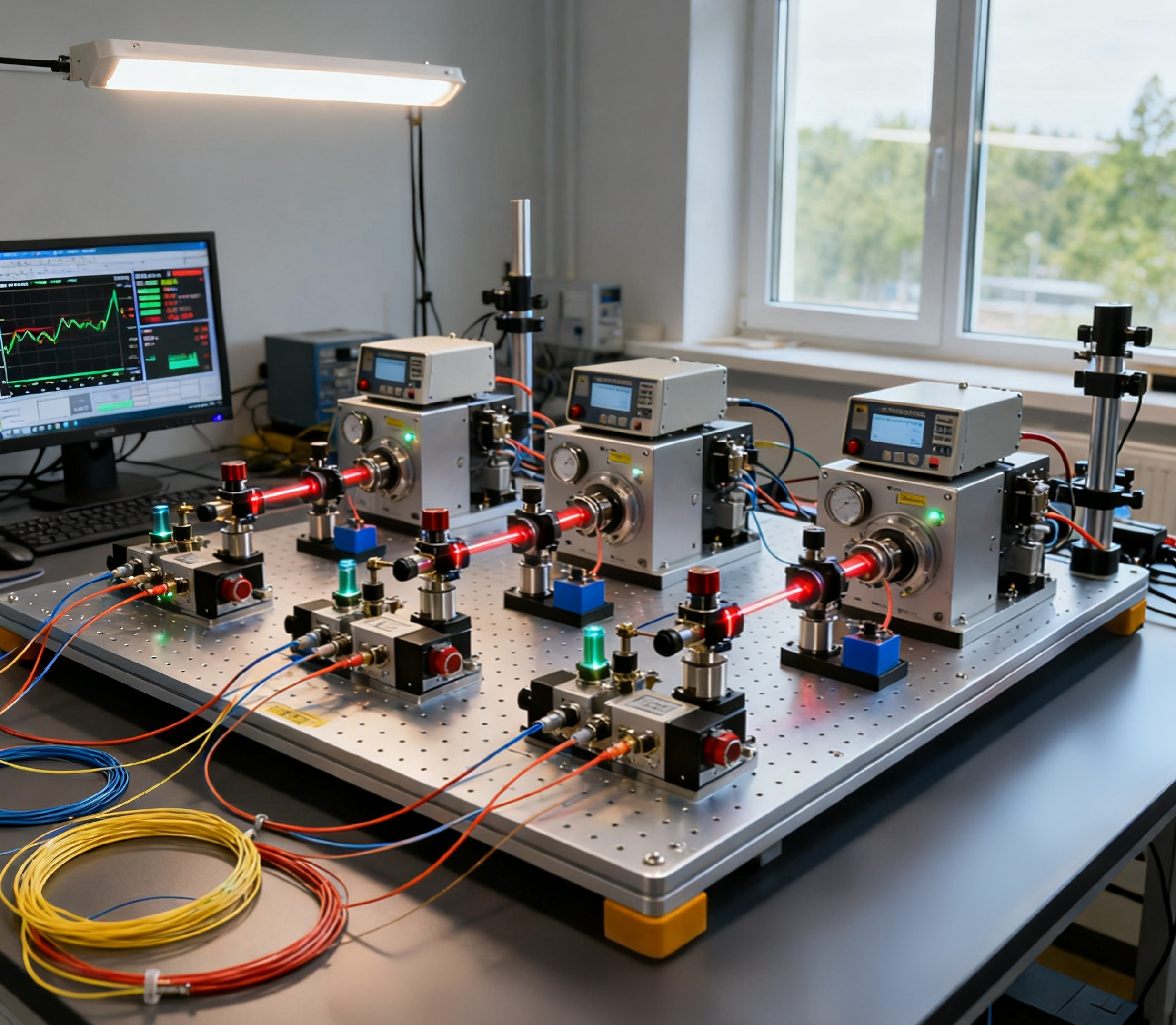

2.Pump-Probe Measurements:

Applications: Investigating ultrafast physical and chemical processes.

Advantages: Optical fibers can be utilized to precisely control the optical path length and stability of the pump and probe beams, thereby streamlining the platform.

3.Laser Cleaning:

Applications: Used for non-destructive and in-situ cleaning to remove contaminants such as rust, paint, films, and grease from the surfaces of materials like metal and glass.

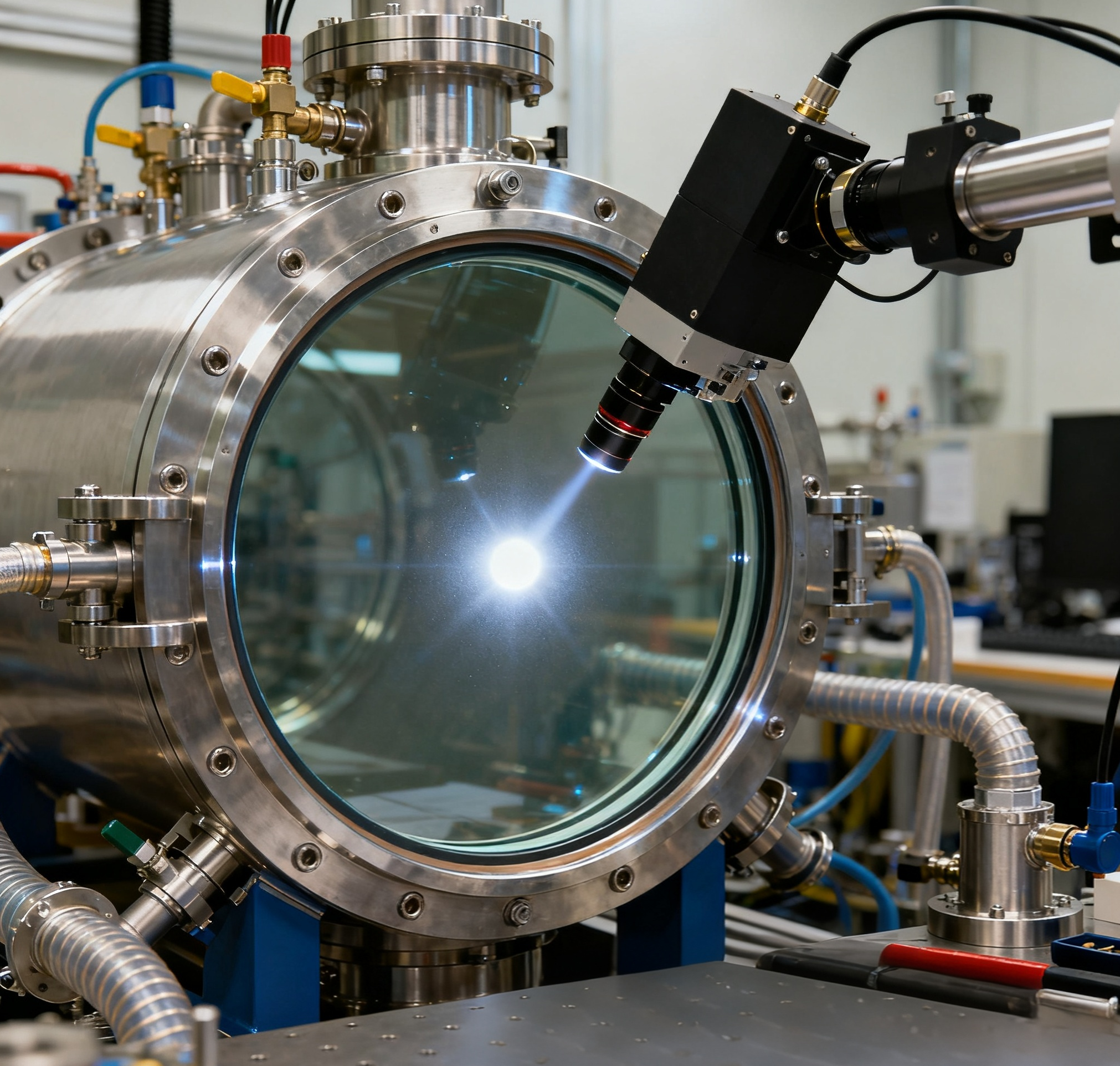

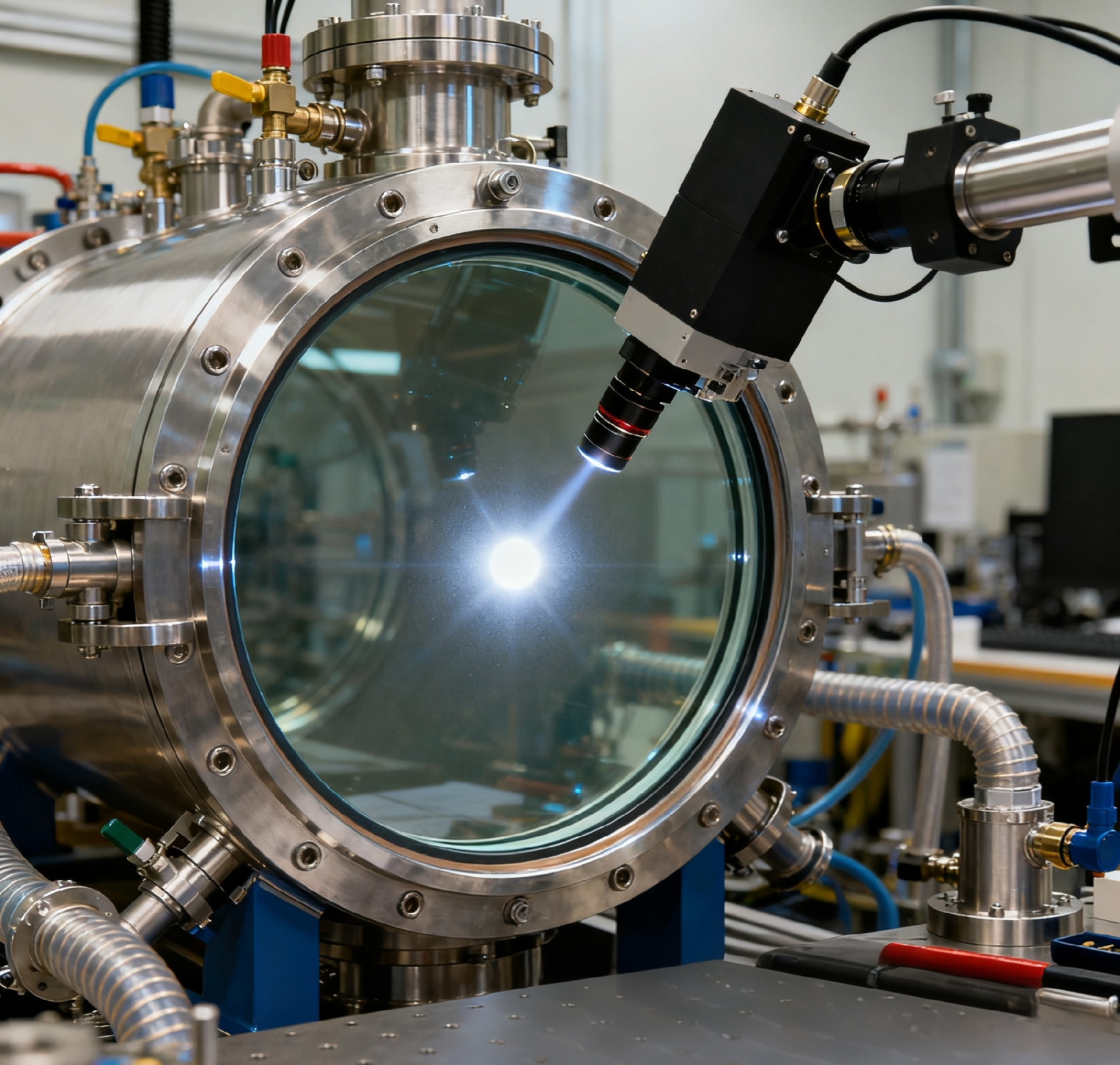

Advantages: Transmit the laser to a cleaning head mounted on a handheld device or a robot arm end-effector by optical fiber provides exceptional operational flexibility. This enables real-time, non-destructive, in-situ cleaning of complex structures like glass windows in high-vacuum environments.