Startorus Fusion continues to deepen integrated innovation in the “AI + fusion” domain. By leveraging advanced computational technologies, the company has achieved a series of significant advances in key areas such as device operation monitoring, plasma control, and diagnostic reconstruction, driving the continuous evolution of device operation toward greater intelligence, reliability, and efficiency.

Intelligent Proactive Warning for critical components significantly enhances device operational safety and maintenance efficiency.

To ensure the safe and stable operation of fusion devices, the system must achieve real-time sensing and accurate early warning of the status of critical components, while processing massive high-frequency data and responding to millisecond-scale transients. Reliance on traditional manual inspections and experience-based monitoring can easily lead to insufficient efficiency and the risk of missed detections.

For example, the fusion magnet power supply system must deliver currents as high as 20 kA, which is difficult for a single power device to handle independently. Therefore, multiple power devices are usually connected in parallel in a bridge-arm configuration. However, this structure is prone to current imbalance or circulating current issues, which, if not monitored in time, can cause power supply failures. Conventional Rogowski coils are susceptible to interference in strong electromagnetic environments, resulting in unstable signal acquisition. In addition, during device operation, the magnet coils carry large currents, and mechanical stress can affect the magnet leads. Even extremely small fluctuations in the resistance of lead joints (typically below 30 μΩ) may cause local overheating or even lead to explosions. Traditional methods struggle to accurately detect such minute resistance variations and cannot effectively assess data reliability.

Therefore, Startorus Fusion has targeted two key indicators—the bridge-arm current of the magnet power supply and the resistance of magnet lead joints—by deploying intelligent anomaly detection systems using data-driven supervised and unsupervised learning strategies, respectively. These systems enable early identification and automatic alarms for abnormal states, significantly enhancing operational safety and maintenance efficiency, marking a critical step toward data-driven and intelligent predictive operation and maintenance of fusion devices.

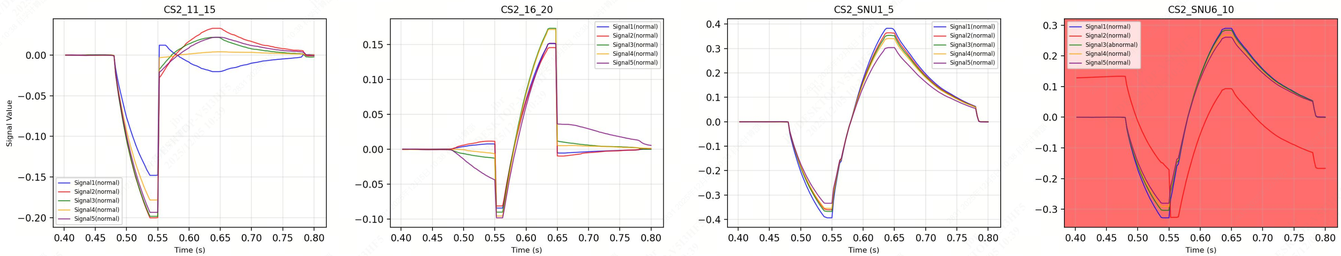

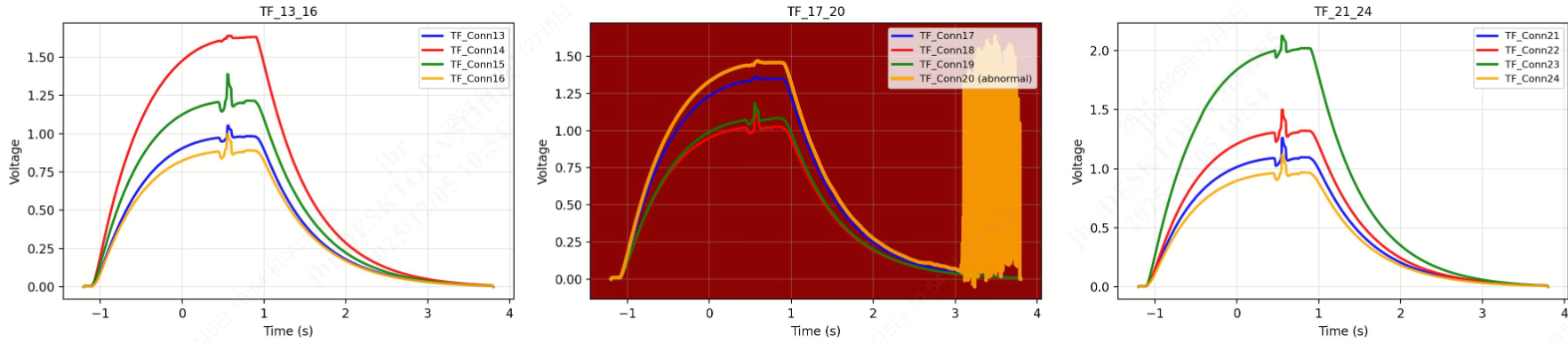

Visualization of magnet power supply bridge-arm currents

Visualization of CS magnet lead joint voltage-drop signals

Visualization of TF magnet lead joint voltage-drop signals

Dual Data- and Physics-Driven Modeling Enables Precise Plasma Control Optimization

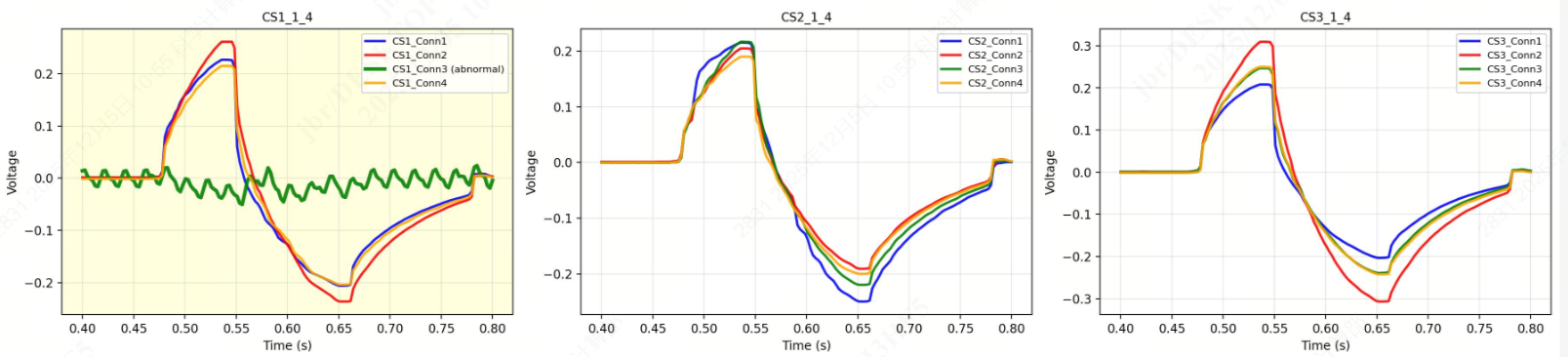

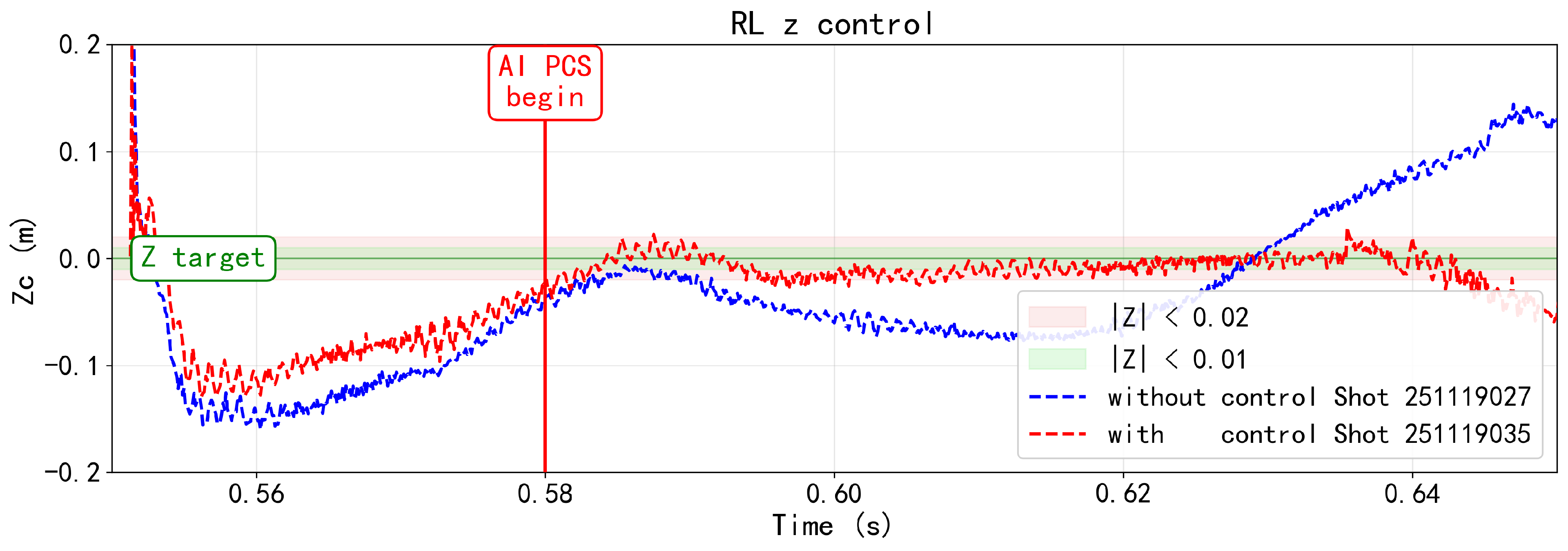

During the operation of magnetic confinement fusion devices, plasma control is characterized by strong multivariable coupling, pronounced nonlinearity, significant temporal dynamics, and rapid variations. These features make traditional strategies that rely on rule-based control or fixed model parameters limited in adaptability under complex operating conditions and costly to adjust. Therefore, Startorus Fusion has leveraged the massive operational data accumulated from the device, together with physics-based plasma free-boundary evolution models, to develop more robust and precise plasma control strategies using reinforcement learning. This approach has preliminarily achieved control over plasma geometric parameters such as the radial position R, vertical position Z, and elongation (κ). It effectively reduces the need for manual adjustments and trial-and-error tuning, further enhancing the precision, response speed, and operational consistency of plasma control, providing efficient and reliable technical support for stable plasma operation.

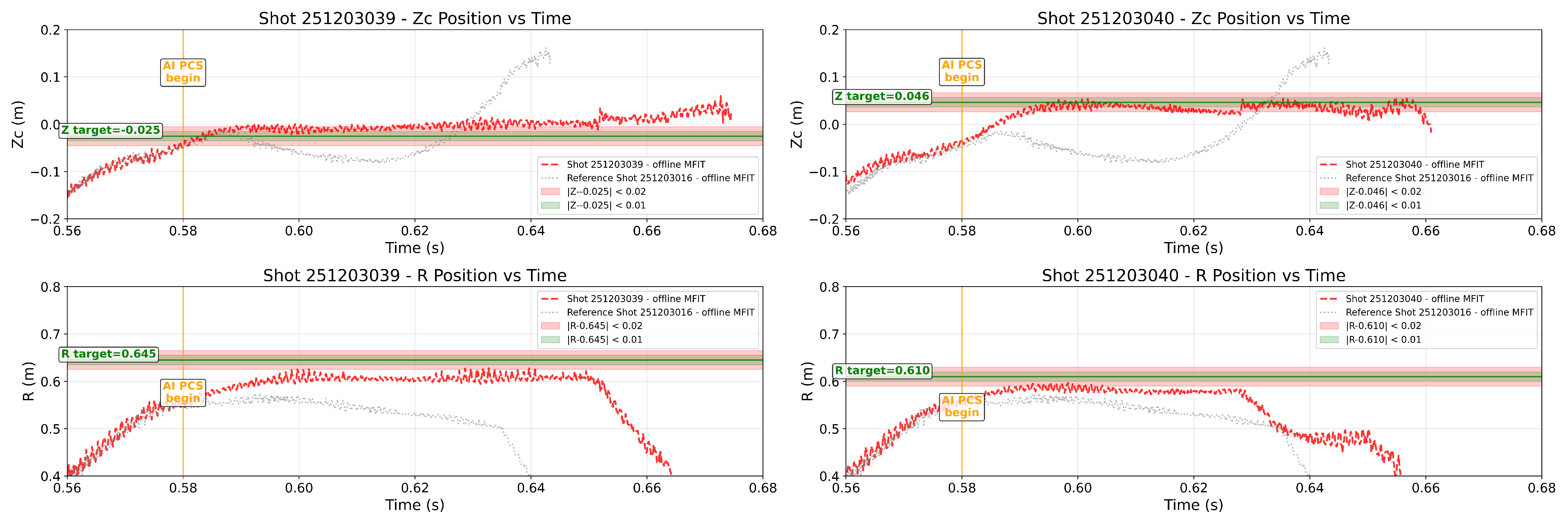

Closed-Loop Stabilization of Plasma Vertical Position (Z) Using a Reinforcement Learning Controller

Left:Setpoint-Change Control(Target Z=-0.025m,R=0.645m) Right:Setpoint-Change Control(Target Z=0.046m,R=0.610m)

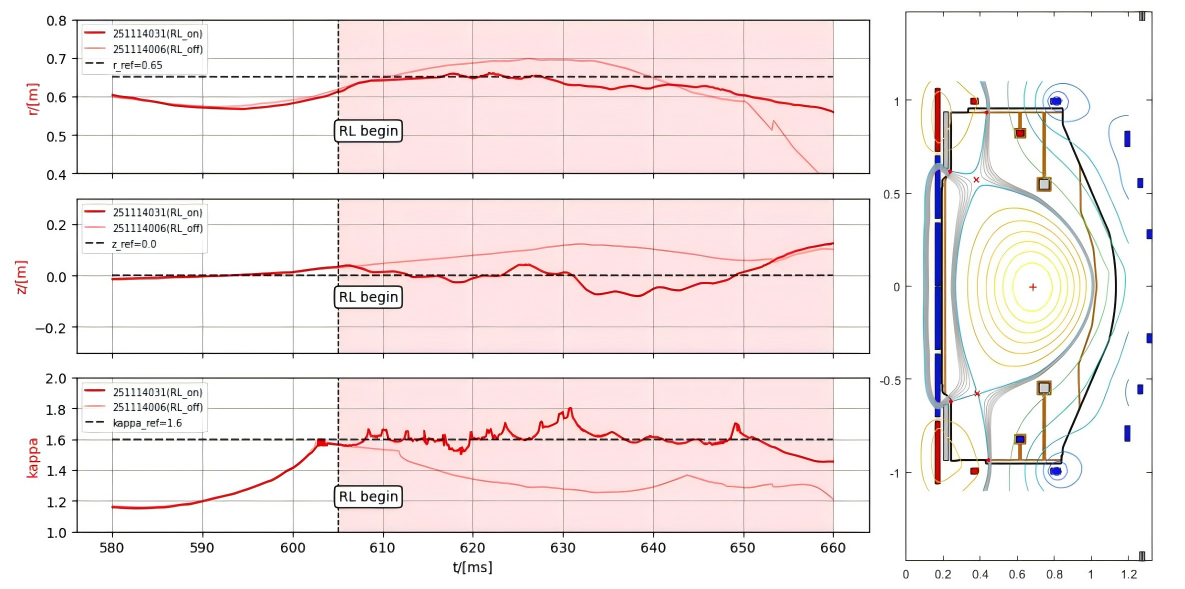

Left:RL-Enabled Control of Plasma Geometry(r/z/kappa) Right:Plasma at Elongation 1.6

Rapid and Efficient Plasma Shape Estimation via a PINNs-Based Forward–Inverse Unified Framework

In plasma equilibrium modeling, the traditional forward problem (equilibrium prediction) and inverse problem (parameter reconstruction) have long been solved independently, resulting in high computational costs and limited real-time responsiveness, with reconstruction accuracy prone to degradation under complex magnetic field conditions. To address this, Startorus Fusion has developed a unified forward–inverse solution framework based on Physics-Informed Neural Networks (PINNs). This model shares information across layers, significantly reducing redundant computation, and enables end-to-end joint reconstruction of plasma equilibrium shapes, key parameters, and magnetic surface structures. Furthermore, the framework demonstrates excellent stability and generalization under sparse or noisy data conditions, with predictions highly consistent with experimental measurements. It achieves superior fitting accuracy and reliability in both shape reconstruction and local magnetic field reconstruction, providing rapid and efficient plasma equilibrium reconstruction.

Intelligent reconstruction Video of Discharge #250703033